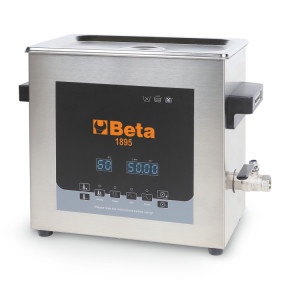

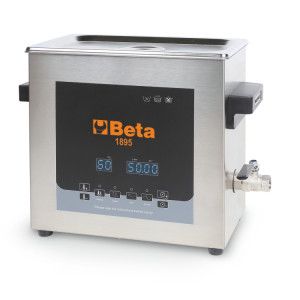

Beta Utensili

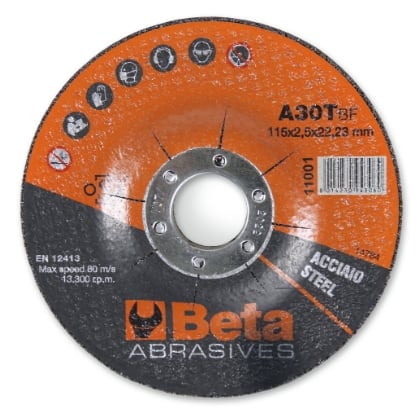

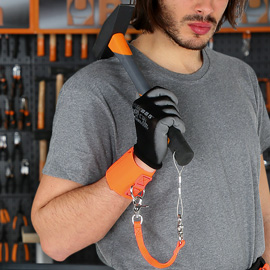

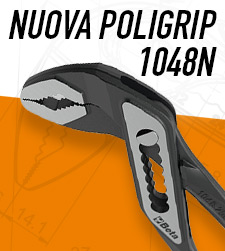

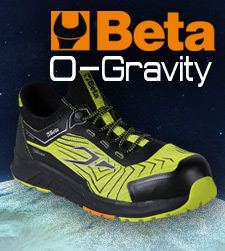

Beta Utensili è leader nella produzione di utensili, strumenti e attrezzi da lavoro professionali. Il catalogo Beta è composto da oltre 16.000 referenze rivolte al professionista dell’industria, della meccanica, dell'autoriparazione, dell'artigianato e del fai-da-te, ma anche agli hobbisti esperti e a tutti gli appassionati. Beta si contraddistingue anche per la gamma di scarpe antinfortunistiche e abbigliamento da lavoro. Il marchio Robur identifica la gamma di accessori per funi e per il sollevamento che rispetta gli stessi severi criteri di qualità dell'utensileria a marchio Beta. Audacia, Impegno, Armonia e Talento sono i valori che guidano ogni giorno i nostri team nella progettazione e produzione di utensili di qualità eccezionale, sicuri e durevoli, costantemente rinnovati per soddisfare le esigenze di ogni utilizzatore che si affida a Beta nella sua attività quotidiana.

Arredamento Officina: Design, Modularità, Organizzazione

Categorie

Beta BENELUX

Beta BENELUX Beta BRASIL

Beta BRASIL BetaCHINA

BetaCHINA Beta FRANCE

Beta FRANCE Beta HUNGARY

Beta HUNGARY Beta IBERIA

Beta IBERIA Beta POLSKA

Beta POLSKA Beta UK

Beta UK